UV Curing: 4 Reasons to Opt for a Hybrid UV System

Business can be a delicate dance between taking initiatives to satisfy short-term needs versus investing in long-term infrastructure. Your equipment purchases must help you process orders today, but be scalable machines that will help you build for the future.

That’s why hybrid UV technologies are red-hot on the converting scene, allowing for maximum long-term flexibility with minimum upfront investment. For more insights, we reached out to Dave Lyus, a Sales Manager-Specialist UV Systems with GEW.

Dave Lyus, GEW

What is UV Curing and What are the Benefits?

Unlike traditional curing methods, which involve heating the printed product to dry the ink, Ultraviolet (UV) curing initiates a polymerization reaction within the ink. Liquid ink is placed on a substrate, which then passes under a UV light.

Within the ink are molecules called photoinitiators. When the UV light hits the photo initiators, a polymerization reaction begins. Molecules join together and create a solid but flexible polymer network. According to Dave, this provides a number of benefits over traditional curing:

Scratch resistance: With UV curing, the cured ink is much more cohesive than inks from traditional drying methods. The strong polymer bond makes the printed piece scratch resistant, and much less likely to be damaged when shipped, for example, reducing waste in the supply chain.

Consistency and vibrancy of colors: Traditional methods will cause nearly a third of the applied ink volume to be flashed off the substrates. With UV curing, 100% of what is put down on the paper will stay there, resulting in 100% yield. This makes achieving the correct color balance for the job easier. The color strength and gloss of the finished print is also better when using UV inks, which increases the shelf appeal of the product.

Inks don’t dry up: Uptime is critical for any converting process. Water-based inks used in traditional curing processes can dry up in the pan, or need to be washed at the end of the workday. With the UV process, until the ink is passed under the lamp, it will stay “wet” forever, due to its chemical makeup, so much less operator intervention is needed.

Two Types of UV Systems: Mercury Arc Lamps and LED Lamps

A mercury arc lamp has been the de facto method for UV curing. With this lamp, mercury vapor passes between an electric arc, which produces the ultraviolet light. The beginning of this video includes a good overview of how mercury lamps work.

The benefits of the mercury arc lamp is that it provides wider wavelengths of UV energy. This makes the job of formulating inks simpler, as there are many photoinitiators from which to choose. The fact that mercury arc technology is well-established means that there is a huge range of mercury-curable inks and coating available today,” Lyus said.

Unfortunately, mercury lamps also produce a lot of heat radiation, which can cause some challenges with different substrates. And they do have a longer warm-up and cool-down period.

Benefits of UV mercury arc lamps

- Better performances with clear-coat varnish

- Hot-melt adhesives more responsive to the lamp’s shortwave frequencies

- Lower investment cost

- Can use wide range of cost-effective inks

Disadvantages of UV mercury arc lamps

- Produces much more heat

- Requires cool-down period

- Requires more energy consumption

In contrast, LED lamps will have one wavelength peak, at the long end of the UV spectrum, and will be “binned” according to what wavelength they output. “You get a lot of power, but it’s only one wavelength,” Lyus said. Here’s a great video which explains how LEDs work.

The high intensity, long wave UV radiation is excellent for penetrating thick layers of ink. The thicker pigment can block out the shorter wavelengths of the mercury lamps. Lyus notes that when you penetrate better, you can run the production line faster and still get a complete cure.

With the limited wavelength output, you need a specially formulated LED ink. You can’t use your mercury-curable inks.

The heat output is also significantly reduced with LEDs. Because the lamps are mounted onto a heat sink, heat is conducted away and not radiated to the material.

Benefits of UV LED lamps

- Better with thick layers and opaque whites

- Requires no warm-up; turn on and off immediately

- Uses less energy

Disadvantages of UV LED lamps

- Limited range of inks and coatings, for now

- A long-term investment

Hybrid UV Systems: Best of Both Worlds

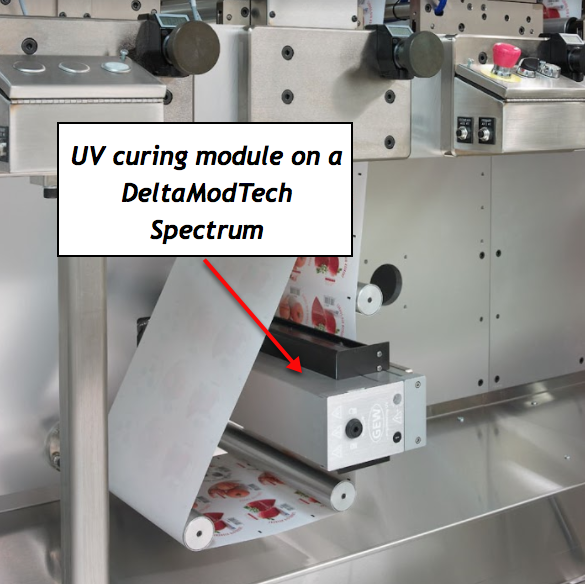

Hybrid systems, like the ones GEW manufactures, allow you to realize the benefits of both mercury arc lamps and LED lights on the same printing machine. By using a modular cassette-based design, you can swap back and forth between the two curing systems to optimize the curing at every print station.

1. Flexibility with inks. Match inks exactly to suit your production job and customer’s requirements – whether these be conventional UV inks, LED-curable, or a combination of the two. Your equipment won’t dictate your decision.

2. It doesn’t have to be a hybrid today. Lyus stresses the need for an “LED ready” hybrid system. If you’re not ready to make the purchase today, you can start with mercury lamps today and add more LED cassettes to the system at the appropriate time in the future.

3. Capability to bid on a wider range of jobs. Because of the inherent advantages of either system, you can take on a wider range of highly-customized jobs.

4. Same performance as a dedicated mercury or LED UV system. The UV technology on the GEW hybrid system is identical to a standard mercury or LED solution; it is the power supply units which allow either or both technologies to operate seamlessly together on the same converting machine.

Click here for a video on GEW’s hybrid system.

UV Curing Equipment With More Flexibility = More Financial Gain

Converting has become dominated by the need for customization and capabilities. It has always been a fine line for converters to walk, and it’s refreshing to see a company like GEW find a solution to help you achieve the best of both mercury arc and LED lamps.

Visit GEW’s website to learn more about their solutions.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Previous Post

A Smarter Converting Option for an NFC Chip Manufacturer