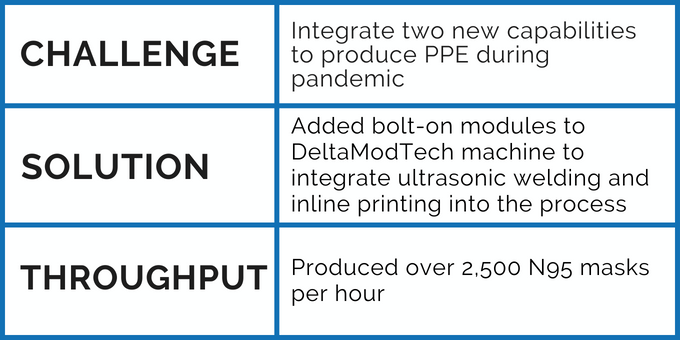

JBC Technologies Integrates Two New Capabilities to Meet Pandemic Demand

Challenge

JBC Technologies is a large-volume precision die-cutter and flexible materials converter. Based in the US, with locations in four states, they’re accustomed to handling challenging projects in multiple industries, including automotive, medical, HVAC, electronics, and more.

That’s the type of work they encounter during normal times, but the newly-arrived pandemic was anything but business-as-usual. When a request came in for a huge quantity of surgical masks, the JBC engineering team was eager to take on the project and close the PPE gap.

The biggest obstacle: The project required inline ultrasonic welding and printing, and JBC didn’t have either capability.

Typically, they’d reach out to Delta ModTech and order a new machine (at the time, they owned three Crusaders.) But the timelines were too tight.

“During the pandemic, lead time for a new machine was 40 to 52 weeks,” recalls Brad Patt, Chief of Operations, “But we didn’t have the luxury to wait a year.” The time frame for completion of the project was less than six months, and JBC would need new capabilities within 4-6 weeks to pull it off.

Solution

Knowing that they couldn’t produce a new machine in the tight project window, Delta ModTech fast-tracked a modular solution. They created two bolt-on modules: An ultrasonic welding module, and a printing module.

Both performed unique production functions. The ultrasonic welding module welded the three different materials together, and the printing module printed specific patent numbers. Delta ModTech also integrated the modules’ controllers into the HMIs so the interface was seamless.

Not only did Delta ModTech deliver the new capabilities, but JBC had them within 4-6 weeks, which allowed them to meet the urgency of the moment.

Throughput

JBC put the new converting system to work, producing tens of thousands of masks per week. All told, they produced more than one million masks.

“The goal was to hurry up, get this thing going and build up an inventory,” said Patt. “We had to get them out to the market as fast as possible.”

The JBC team worked first and second shifts to meet the demand; no small feat considering the work was being done in the middle of a pandemic.

Once the project was done, JBC transitioned the machine into regular production equipment. Eventually, the capabilities were applied to new opportunities, which made the investment both a short- and long-term win.

“We dipped our toes into it faster than we wanted,” Patt said. “But in hindsight, it was beneficial for both the organization and the individuals involved.”

Five and counting…

Patt noted that his team relies on Delta ModTech for its technical expertise and the equipment performance — and that includes delivering under pressure, as was the case with the surgical masks.

It’s a big reason why JBC now owns five Delta ModTech Crusaders, more than any other type of converting equipment.

“They’re at the top of the heap,” said Patt.

OVERCOME YOUR BIGGEST CONVERTING AND PACKAGING CHALLENGES

Published on Jun 13 2023

Last Updated on Aug 07 2024

Categories: Case Studies, Converting, Die Cutting, Medical Devices, News

Next Post

Delta Hosts Local Robotics Camp

Previous Post

Delta ModTech and Frontier at Hydrogen Technology Expo